Credits: Article and images by Justin Koullapis @ Quill & Pad. See the original article here - https://quillandpad.com/2024/11/19/the-omega-spirate-system-a-new-idea-in-balance-spring-technology-2/

—————————————————————————————————–

There is some new terminology. Terms in bold type are from Omega; the others are our own:

In Figure 1, there is the Loading Beam. This can be moved slightly left or right. At its free end is the Loading Beam Tip. This is held in the lower of the two studs shown in Figure 2.

Figure 2. As seen on the rear cover, but with the Blocker removed, showing the

anti-backlash horseshoe spring to the left, acting on the ‘Rate Mobile Stud Holder’. This can be moved by a snail concealed under the calibrated Tuner at the right.

The upper end of the Loading Beam terminates at the part shaped like an archer’s bow. This rigid bow hardly flexes, ensuring that any motion of the Loading Beam is directed at introducing tension or compression into the Blade.

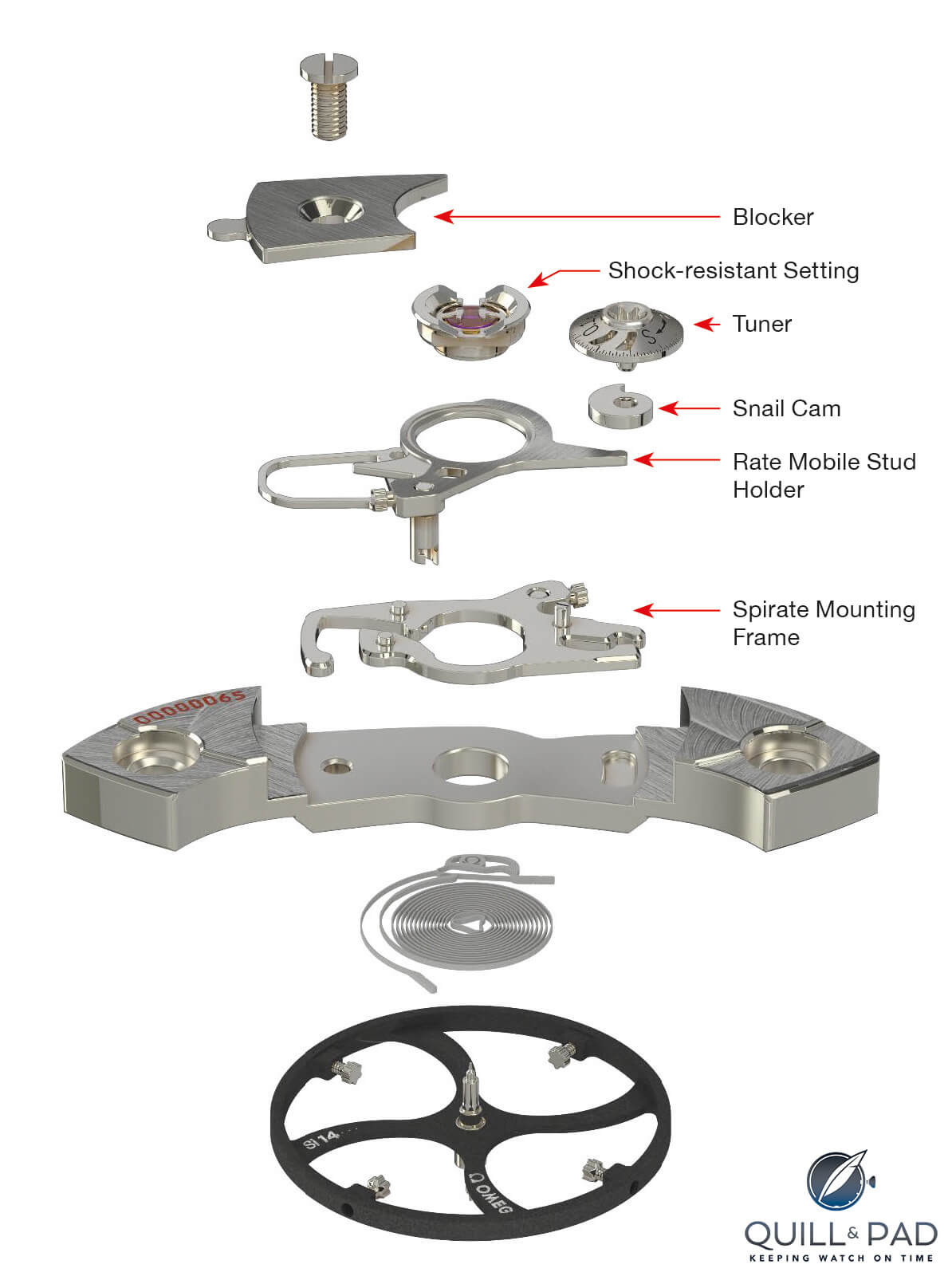

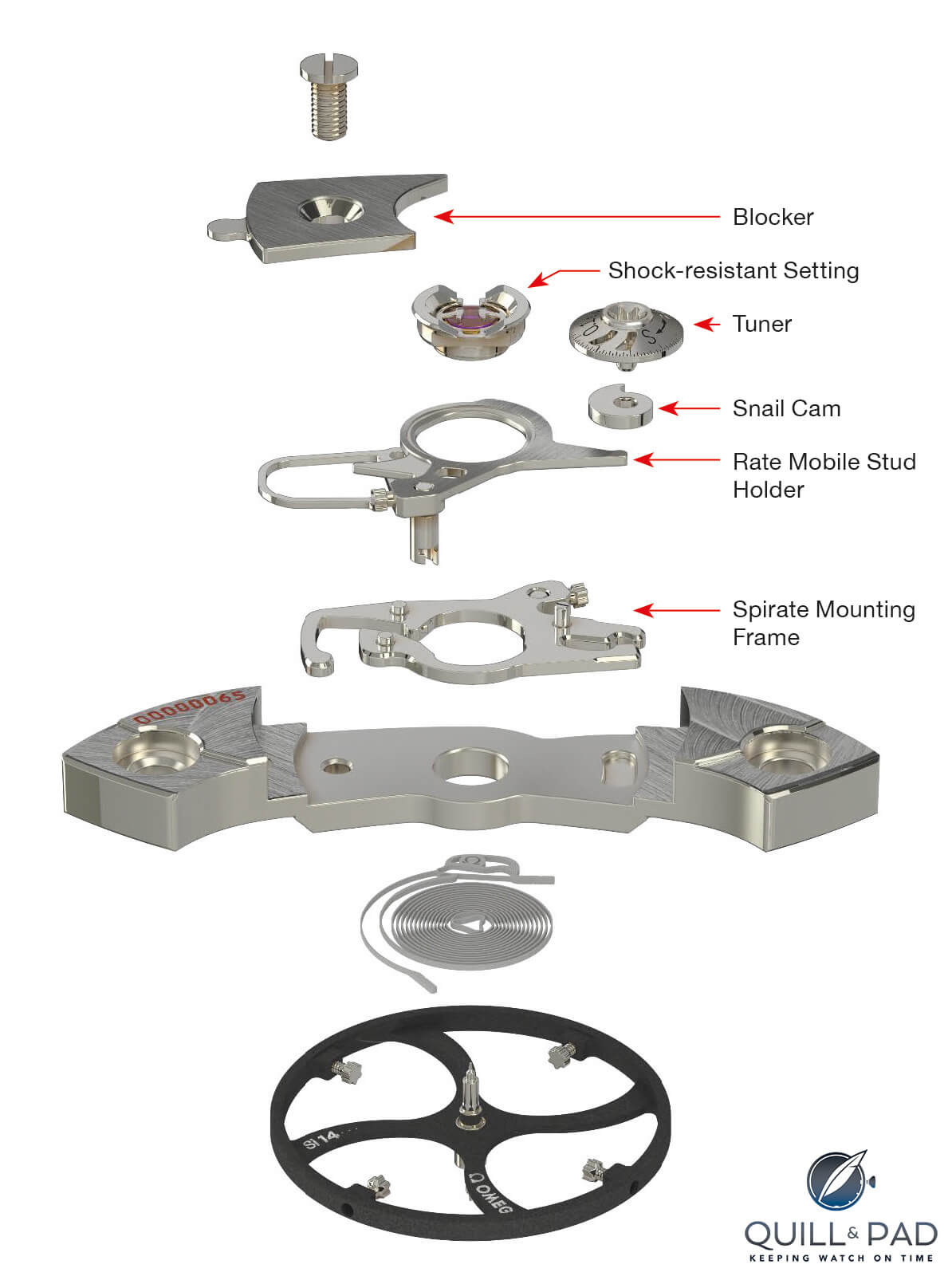

Figure 3. The relative positions of the system components in exploded view.

The mounting frame can be moved for beat adjustment.

Adjustment is made by rotating the calibrated Tuner, Figure 3. This rotation (via the Snail Cam, normally hidden from view) causes the Rate Mobile Stud Holder, to rotate slightly. It carries the stud referred to earlier, which in turn holds, and moves, the Loading Beam Tip.

The whole spring is attached to the watch by the Stud Embedding Point, which points rightward near the top. This is held rigidly in the upper stud. The entire assembly can be rotated to put the watch in beat.

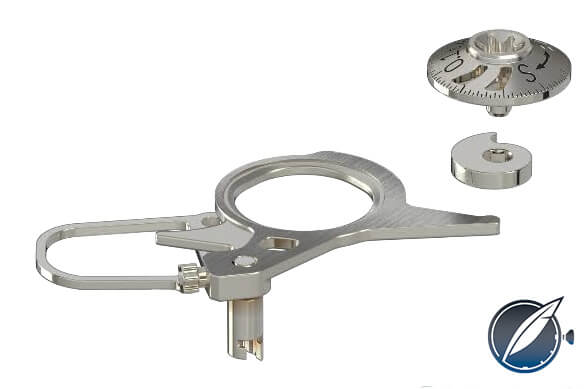

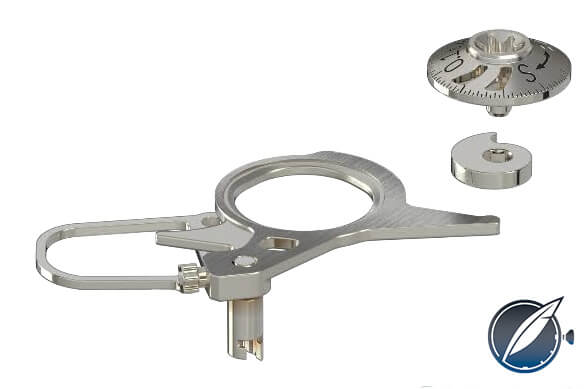

Figure 4. Details of the Spirate calibrated rate adjustment. The Rate Mobile Stud Holder follows the snail cam’s motion. The stud descends below the cock, grasping the tip of the balance spring’s Loading Beam.

The Rate Mobile Stud Holder, the Snail Cam, and the calibrated Tuner are shown in more detail in Figure 4.

The Rate Mobile Stud Holder as depicted in the photos of the watch has a +/- engraved onto it (although it’s not shown in the exploded views). This was quite a red herring when we tried to analyze the Spirate early on because it seemed that the associated fluted-head screw was some type of adjuster.

The +/- is only an emblem, indicating that the whole part moves to alter the rate. The fluted-head screws here and on the opposite side are simply clamping screws to hold the studs in place.

There are notches in the spring’s Stud Embedding Point and the Loading Beam Tip. These are for mechanical gripping within the studs, which is more sure than glue with this material. The spring is made by Deep Reactive Ion Etching (DRIE) of oxidized monocrystalline silicone, at Asulab, Swatch Group’s research and development laboratory.

You can visualize from Figure 4. how the Tuner is keyed to rotate as one with the Snail Cam. The rightmost limb of the Rate Mobile Stud Holder is a cam follower, pressed into permanent contact by the action of the horseshoe spring visible to the left in Figures 2 and 4.

As the Tuner is rotated, the snail causes the Rate Mobile Stud Holder to pivot slightly around the shock-resistant setting, flexing the Loading Beam slightly left or right.

—————————————————————————————————–

Credits: Article and images by Justin Koullapis @ Quill & Pad. See the original article here - https://quillandpad.com/2024/11/19/the-omega-spirate-system-a-new-idea-in-balance-spring-technology-2/