Credits: Article and images by Ian Skellern @ Quill & Pad. See the original article here - https://quillandpad.com/2024/02/24/burgess-clock-b-is-the-worlds-most-precise-pendulum-clock-and-is-made-to-a-250-year-old-design-by-john-harrison-longitude-prize-winner-and-inventor-of-the-marine-chronometer/

—————————————————————————————————–

Clock B completed by Charles Frodsham & Co.

To complete Clock B, Charles Frodsham & Co. under the direction of Philip Whyte and Richard Stenning consulted extensively with a team of distinguished horologists in the Harrison Research Group, which included William Andrewes, Andrew King, Donald Saff, Burgess, Mervyn Hobden, and others.

Frodsham watchmakers Roger Stevenson and Martin Dorsch as well as other team members designed and produced the missing components for Clock B and tested it extensively in 2012.

It was decided to compete the clock according to Harrison’s design and principles but using modern technology where appropriate. For instance while the clock is driven by a descending weight, the weight is automatically wound up by an electric motor.

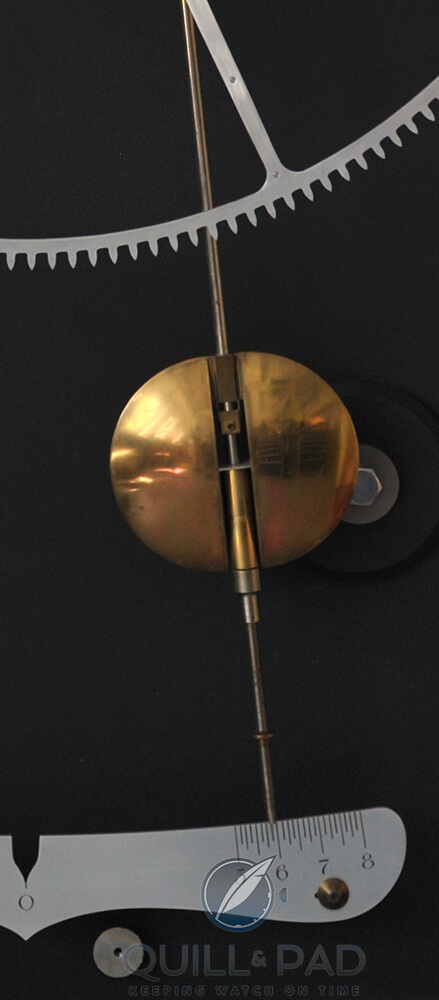

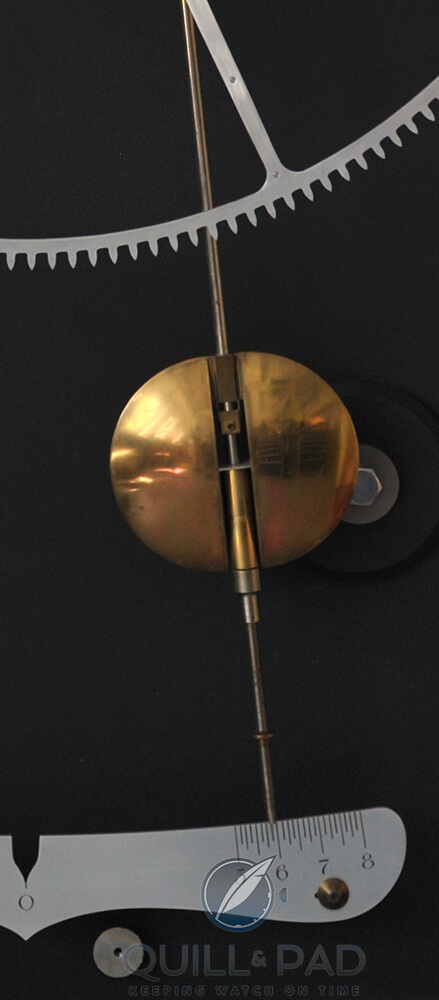

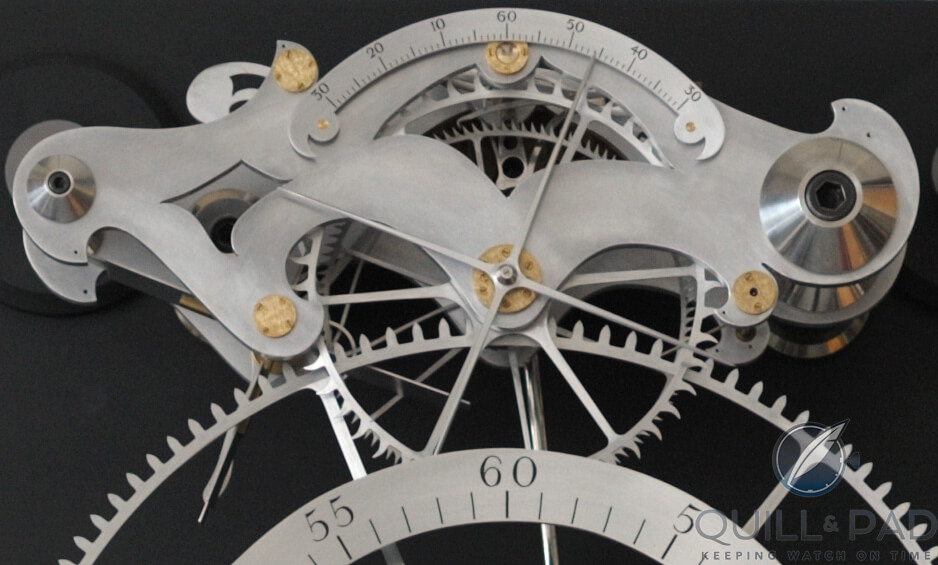

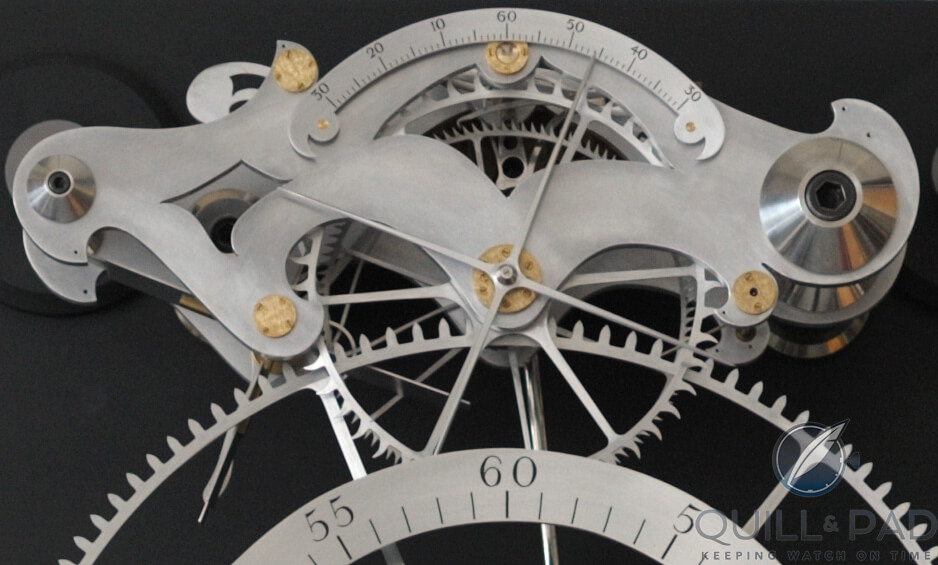

Pendulum of the Burgess Clock B, completed by Charles Frodsham & Co.

Clock B’s gear train wheels are made of Duralumin, which run on oil-free bearings. The pinions are Harrison’s form of lantern pinions but use small ball races in place of Harrison’s lignum vitae wooden rollers.

Harrison’s regulator clocks do not require lubrication, and Burgess planned the same for Clock A and Clock B. The former has been keeping good time oil-free for near 30 years with virtually no maintenance.

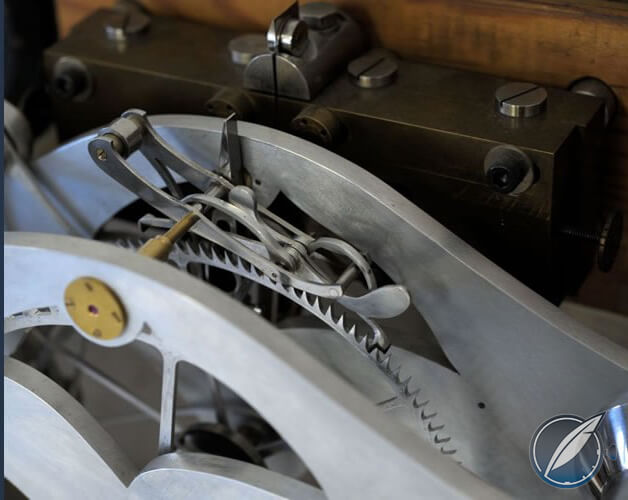

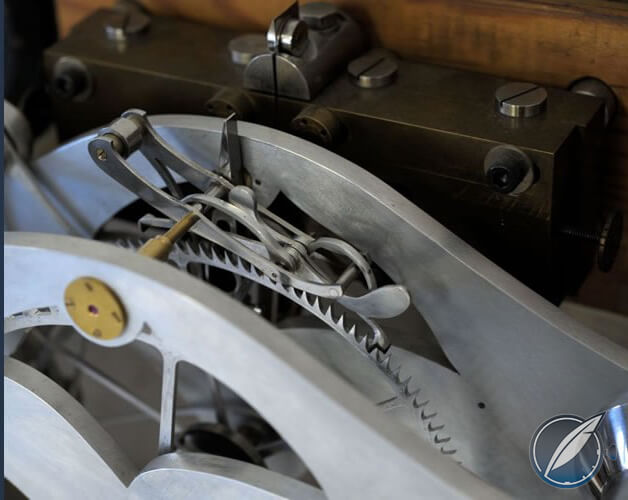

Clock B is regulated by a low-friction, lubrication free Grasshopper escapement, which was invented by Harrison.

The Burgess Clock B features a Grasshopper escapement (pictured here in an unfinished state), which is a John Harrison invention

The escape wheel is driven directly by a remontoir, which is a coiled spring that rewinds every 30 seconds. This isolates the escapement from variations in torque from the gear train and ensures that the recoil of the escape wheel just rewinds the remontoir spring rather than the whole gear train.

The Burgess Clock B, completed by Charles Frodsham & Co.

Building on lessons learnt by Burgess, for Clock B Frodsham made a new pallet arbor resting on sapphire pads and used low friction PEEK for the pallets and composer bearings. The cycloidal suspension cheeks are a very important part of Harrison’s regulator theory, and these were precision milled from large brass blocks bolted to the massive 90-kilogram steel back plate.

Burgess Clock B, completed by Charles Frodsham & Co.

Much more work was required to complete the drive to the hands, the dials, and the hour, minute and second hands; the aesthetics were carefully agreed with the clock’s owner.

—————————————————————————————————–

Credits: Article and images by Ian Skellern @ Quill & Pad. See the original article here - https://quillandpad.com/2024/02/24/burgess-clock-b-is-the-worlds-most-precise-pendulum-clock-and-is-made-to-a-250-year-old-design-by-john-harrison-longitude-prize-winner-and-inventor-of-the-marine-chronometer/